1

/

of

6

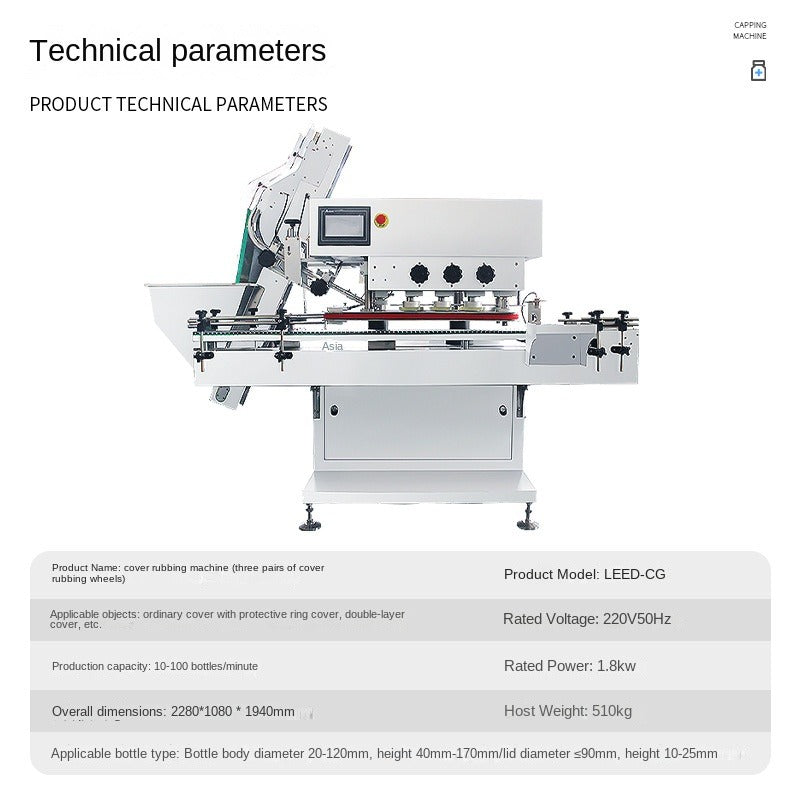

Automatic high speed capping machine for bottle screw capper

Automatic high speed capping machine for bottle screw capper

Gainjoysmachine

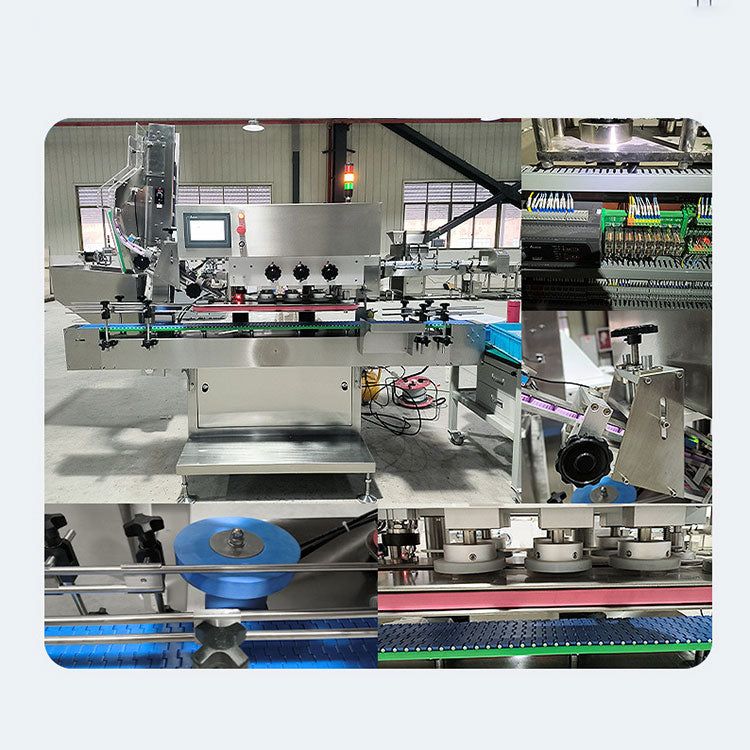

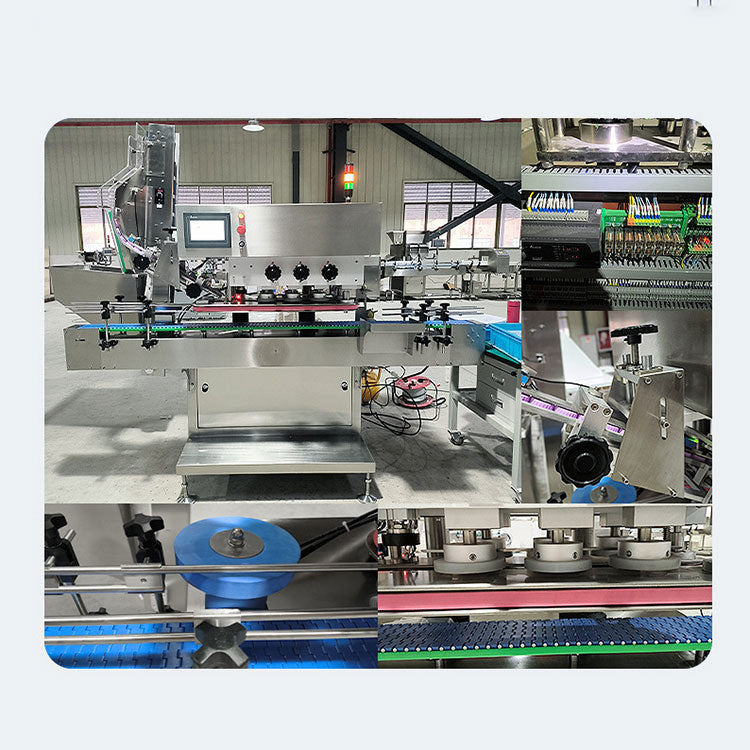

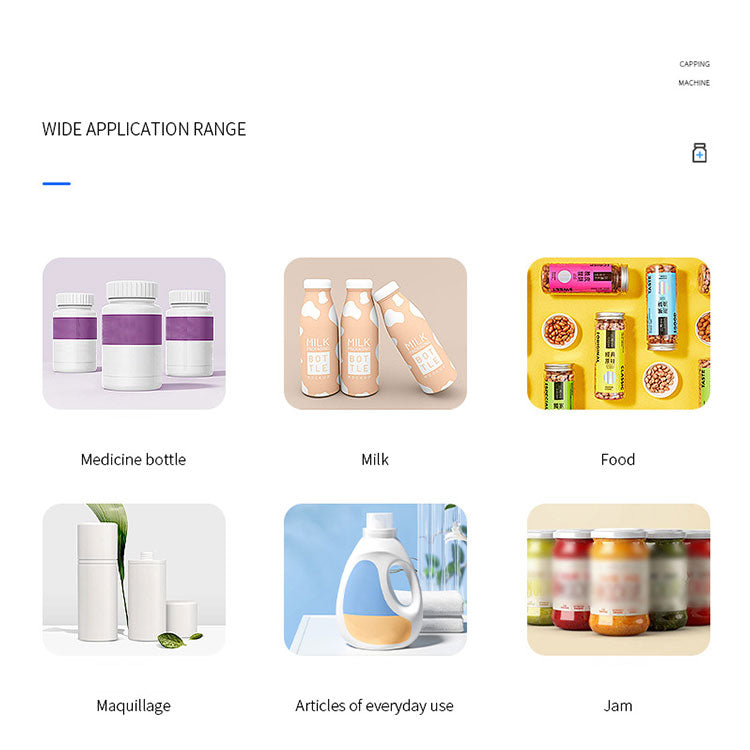

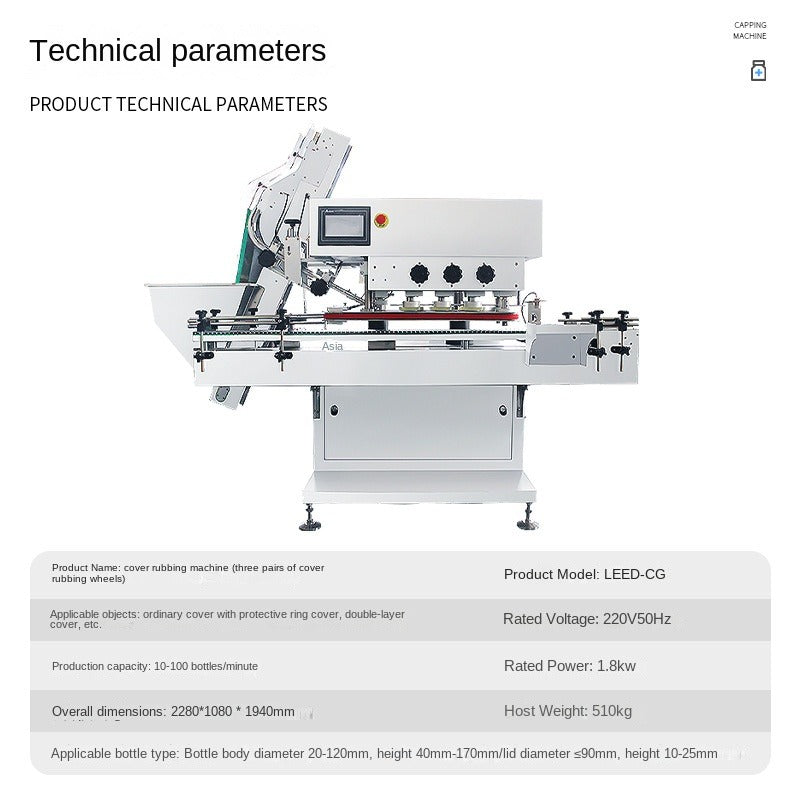

The capping machine usually consists of the following parts: feeding system, positioning system, capping system, and control system. Firstly, the container will enter the capping machine through the feeding system and be accurately positioned through the positioning system. Then, the capping system will grab the appropriate bottle cap from the feeder and screw it into the bottle mouth under the guidance of the capping head. The capping process can adapt to different types of caps and bottle mouths by adjusting the torque and speed of the capping head. Finally, the control system monitors and controls the entire capping process to ensure stable and efficient operation.

Capping machines have many advantages. Firstly, it can efficiently complete the sealing of bottle caps and improve production efficiency. Secondly, the capping machine has high accuracy, ensuring that each bottle cap is fully screwed into the correct position. In addition, capping machines typically have automated functions, reducing the need for manual operations and improving the efficiency and hygiene standards of the production line.

View full details

Capping machines have many advantages. Firstly, it can efficiently complete the sealing of bottle caps and improve production efficiency. Secondly, the capping machine has high accuracy, ensuring that each bottle cap is fully screwed into the correct position. In addition, capping machines typically have automated functions, reducing the need for manual operations and improving the efficiency and hygiene standards of the production line.