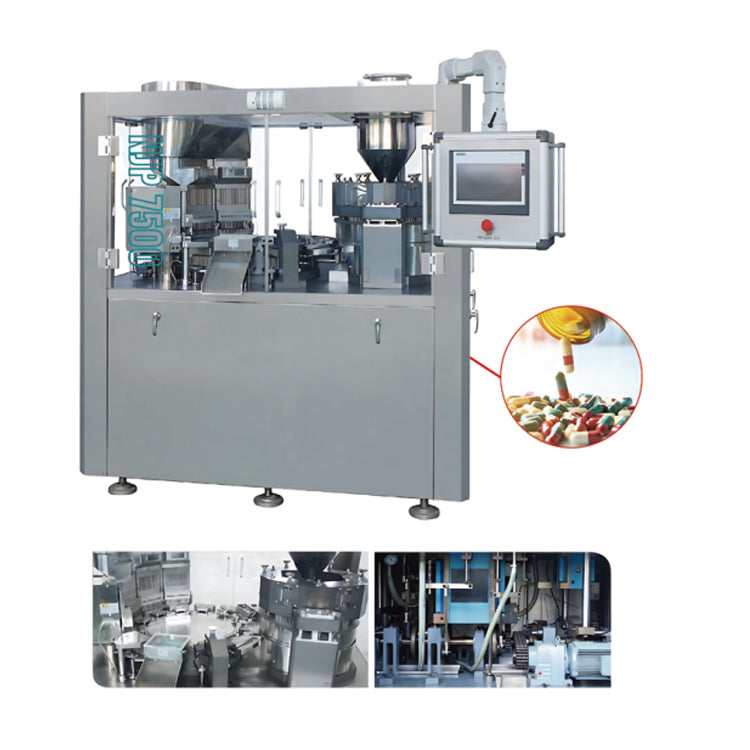

Automatic Capsule Filling Machine

Automatic Capsule Filling Machine

Gainjoysmachine

An automatic capsule filling machine is a specialized pharmaceutical and nutraceutical manufacturing equipment designed to automate the process of filling empty gelatin or vegetable capsules with precise amounts of powdered or granulated substances. This machine is widely used in the pharmaceutical industry, as well as in the production of dietary supplements, herbal products, and other encapsulated formulations. The primary purpose of the automatic capsule filling machine is to streamline the capsule filling process, increase efficiency, and ensure accurate dosage.

Here are some key features and components commonly found in automatic capsule filling machines:

-

Hopper System: The machine typically includes a hopper that holds the bulk quantity of the powdered or granulated material to be encapsulated. This hopper feeds the material into the dosing unit for accurate filling.

-

Dosing Unit: The dosing unit is responsible for metering and dispensing the precise amount of material into each capsule. It ensures uniformity in dosage across all capsules.

-

Capsule Magazine: Empty capsules are stored in a magazine or hopper, ready to be filled. The machine automatically separates and positions the capsules for the filling process.

-

Capsule Orientation System: This system orients the capsules in the correct position for filling. Capsules have two halves, and it's essential to align them properly to ensure accurate dosing.

-

Filling Stations: Automatic capsule filling machines have multiple filling stations, each equipped with a dosing disc or other mechanism to fill the capsules. The number of filling stations can vary based on the production capacity and the complexity of the filling process.

-

Tamping or Leveling Mechanism: After filling, a tamping or leveling mechanism is often used to compact the material within the capsules, ensuring consistent and accurate dosing.

-

Capsule Closing Station: Once filled, the two halves of the capsules need to be sealed. The machine includes a mechanism for joining and closing the capsules securely.

-

Control System: These machines are equipped with advanced control systems that allow operators to set and monitor parameters such as fill weight, capsule size, and production speed. Some machines also have automatic rejection systems for capsules that don't meet quality standards.

-

Cleaning and Maintenance Features: To comply with hygiene and safety standards in pharmaceutical manufacturing, automatic capsule filling machines are designed for easy cleaning and maintenance.

-

Output and Efficiency: These machines can achieve high production speeds, making them suitable for large-scale manufacturing. The efficiency of the process minimizes labor requirements and reduces the risk of errors associated with manual capsule filling.

Automatic capsule filling machines contribute significantly to the pharmaceutical and nutraceutical industries by improving production efficiency, ensuring dosage accuracy, and meeting regulatory standards for quality and consistency in capsule formulations.